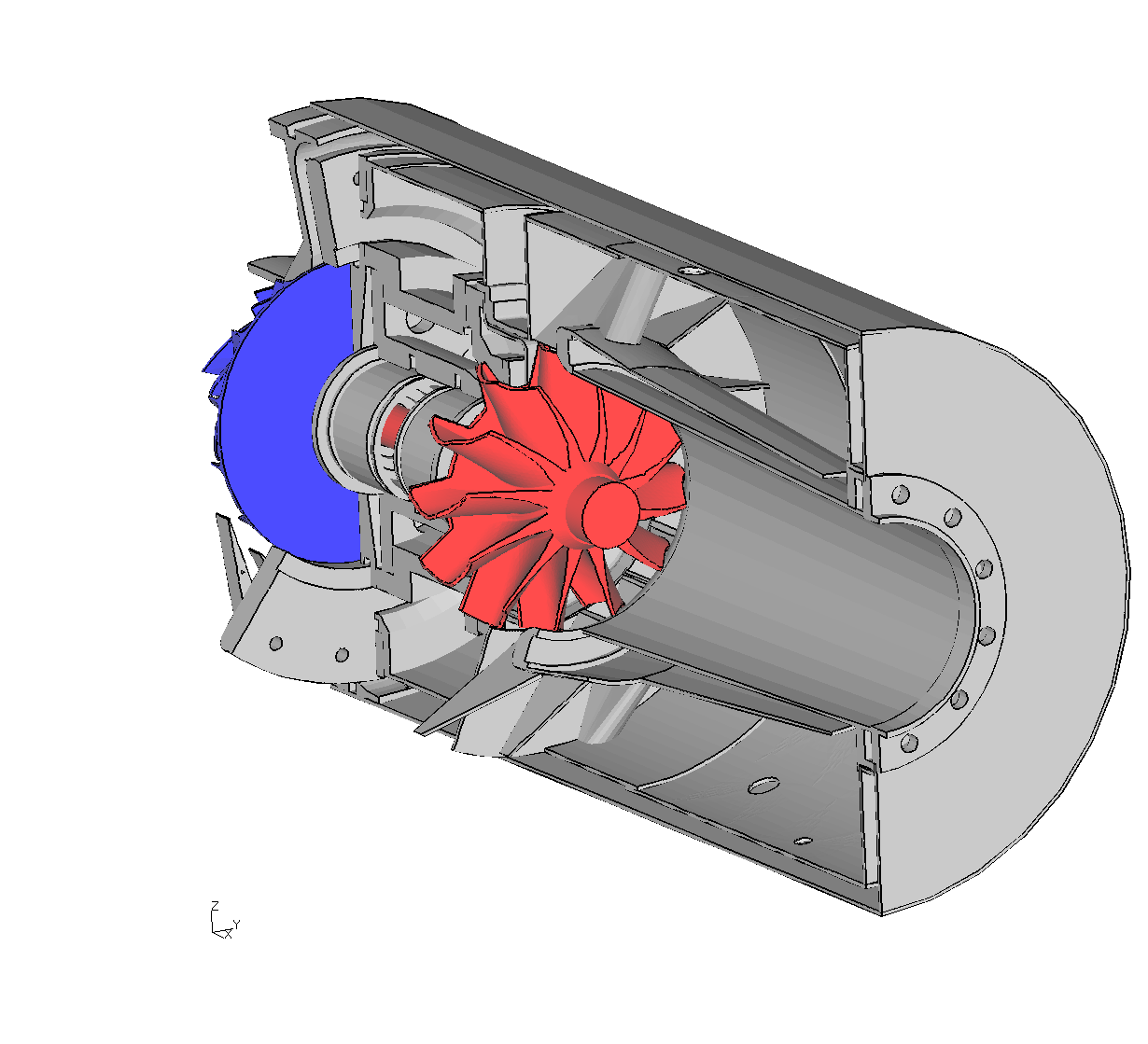

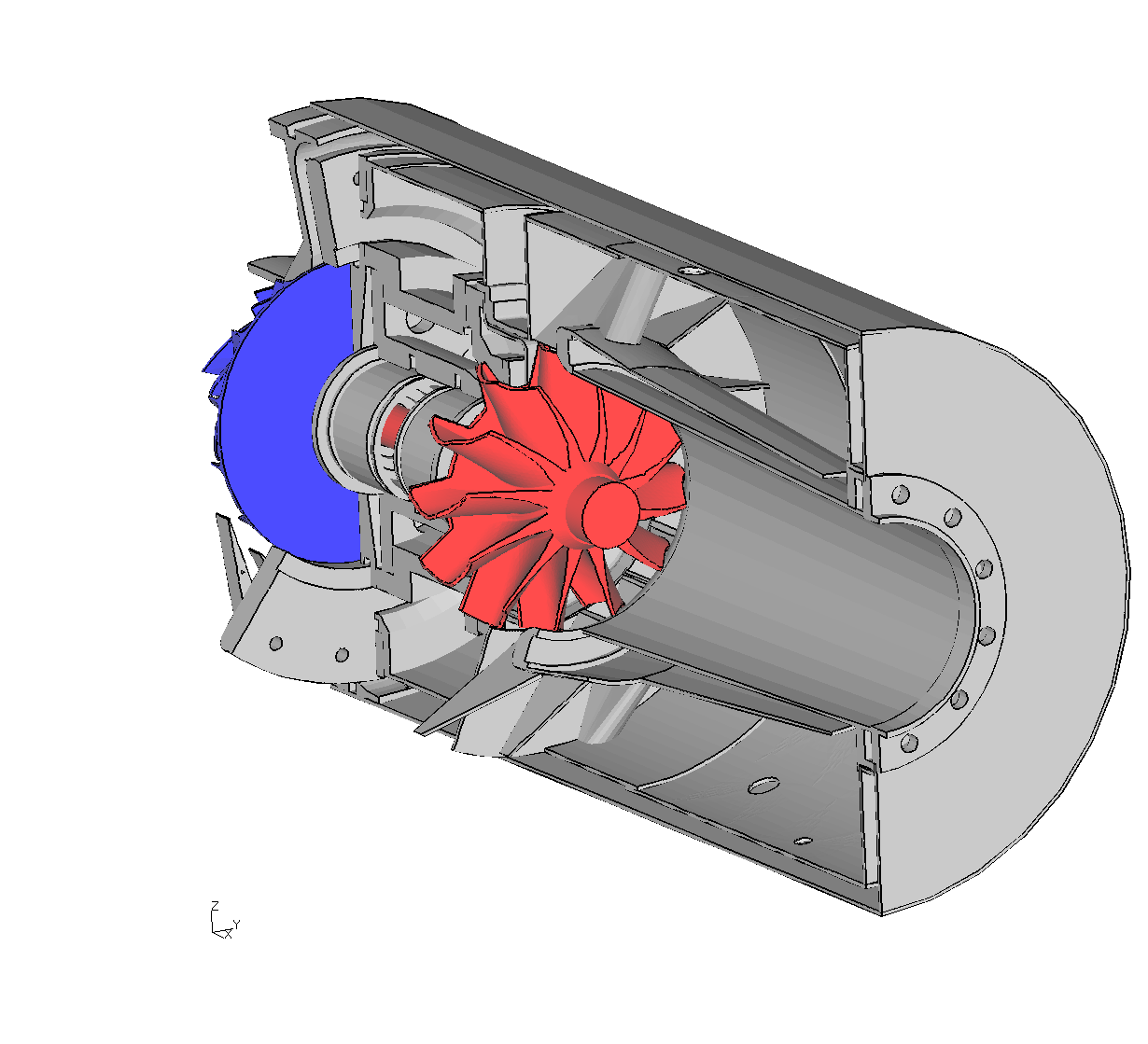

Rear

view of the jet-engine FE-model

Click here to get

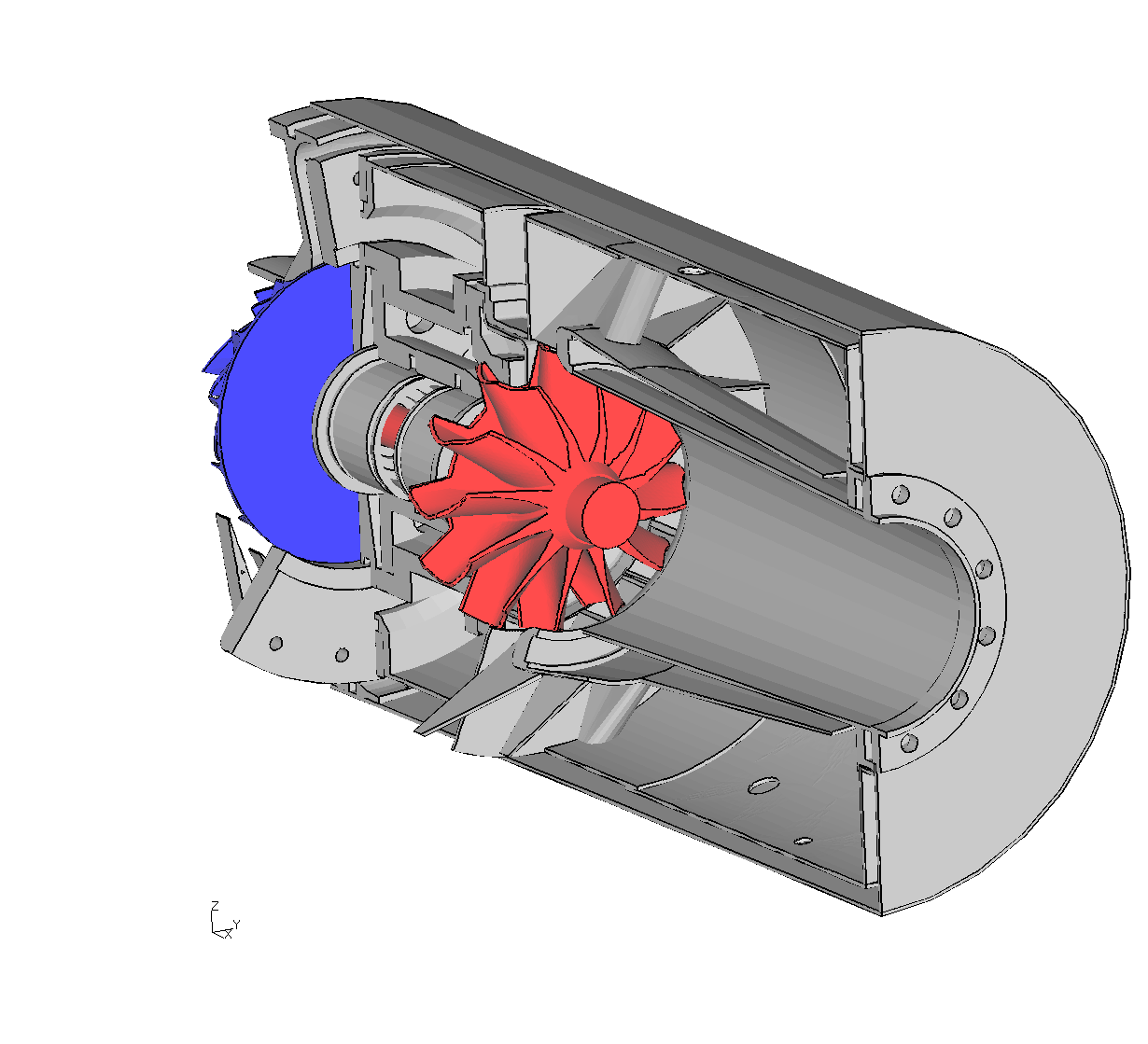

The package includes a 3D- and a 2D model. There are no boundary conditions

applied on the 3D model. The intention is to give insight in

the way cgx deals with geometry and how certain parts are designed in cgx. The

2D model was derived from the 3D model and includes all necessary boundary

conditions and the solver file for a thermal calculation.

Some documentation of the jet-engine project is available. The documentation is in German

language. The first part lists the specification, gives technical background

of the engine and explains the detailed anaytical design of all components. The

testing of the real engine is documented in the three build-reports.

Photos of the test-bed and of the disassembled engine can be found in the

documentation of the second build.

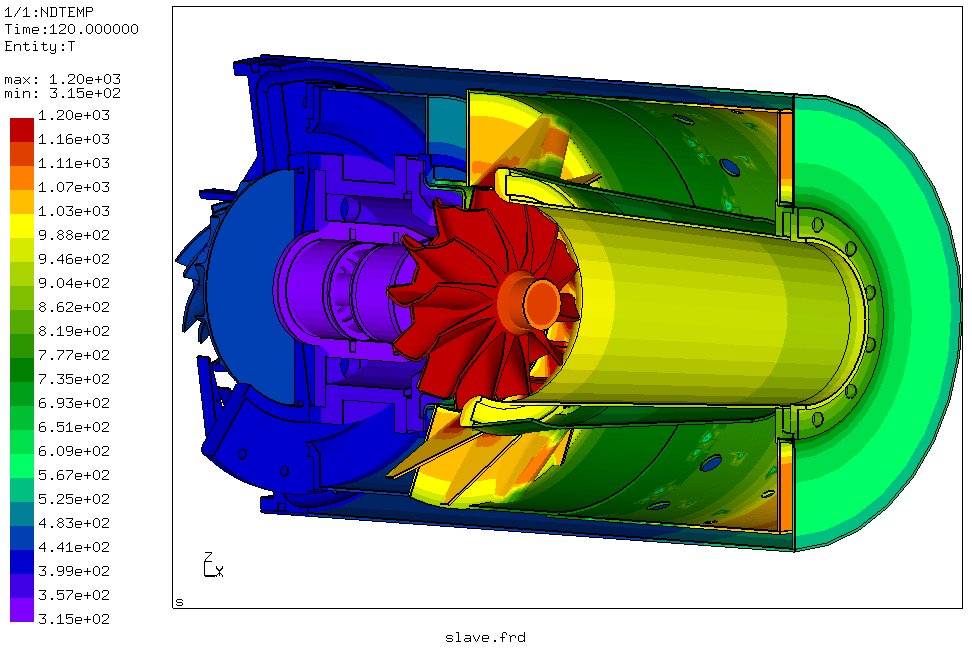

A 2D thermal model was created based on the formulas and results as stated in the

documentation listed above:

Time dependent temperatures [K]. 2D-model with 1D-thermal network.

From cold to full rated in 3 sec, then 117 sec at full rated conditions.

(This is an animated gif file)

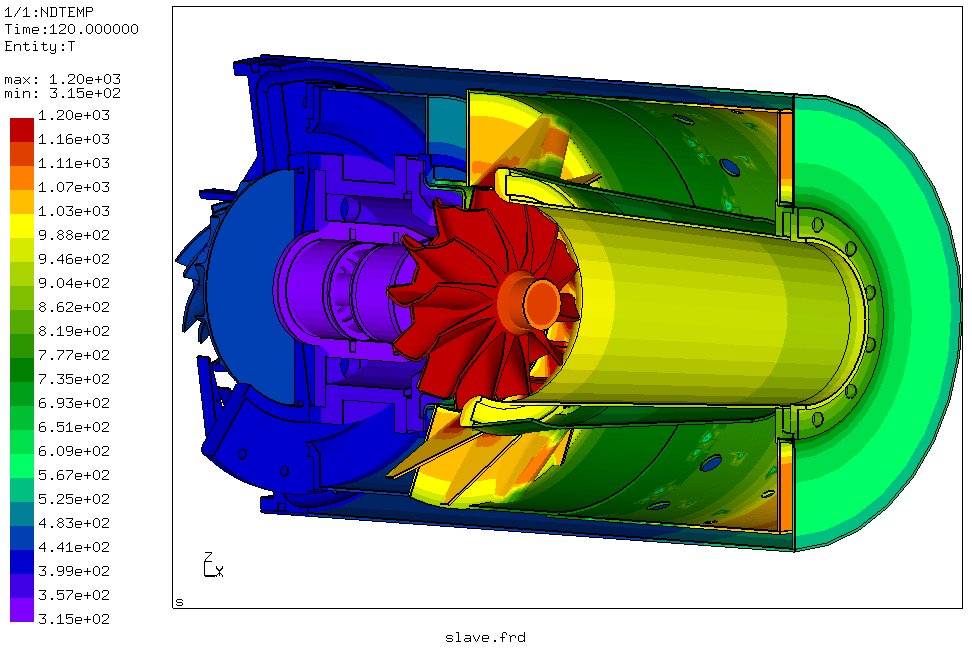

The 2D thermal results were mapped on the 3D model:

Mapped temperatures [K], after 117 sec at full rated conditions.

PrivacyPolicy

Legal Disclosure